- manual wrappers (operated manually). These are most often turntable wrappers with manual control, i.e. the machines are not equipped with programmer that enables repetitive wrapping of pallets. Manual control machines are dedicated to warehouses packaging few pallets per day

- semi-automatic wrappers. Here, the leading position belongs also to wrappers with turntable. Used automation enables saving program with work parameters. Thanks to this, pallets are packed in a repeatable way, which translates into appropriate repeatability of pallet protection quality and control over wear and tear, and what follows – over costs of stretch film used for wrapping a load.

- automatic wrappers. They are mostly chosen by clients expecting full integration of pallet wrapping process. They can be the last element of a production line or a robotized station of palletizing loads on pallets

Investment in pallet wrapping machine – is it profitable?

Purchase of the machine for wrapping pallets with stretch film (or net) brings many benefits. Based on our experience we can confirm with full responsibility that:

- pallet wrapping machine reduces costs of protecting a pallet. Using dedicated machine stretch films we limit consumption of film needed to wrap a pallet. By using a film stretching system, we can significantly reduce the amount of stretch film used, whereas over the last few years friction stretching wrapping machines working with thin prestretch films or blocked nano-films have become increasingly popular. Depending on the used film in comparison to manual wrapping we can reduce stretch film consumption even by 50%

- machine protection of a pallet means better protection and stabilization of the pallet. By choosing a semi-automatic or automatic machine, we can precisely adjust the parameters of wrapping the load on the pallet. Thanks to this we are sure that goods packed in such a way will safely reach the point of destination

- increase work efficiency thanks to the possibility of working in a semi-automatic or automatic cycle. Securing a pallet with the use of a pallet wrapping machine lasts much shorter compared to manual wrapping and the operator has time to perform other activities, e.g. preparing other pallets, putting the wrapped pallets back, entering data into the system, etc.

- significantly improve ergonomics. Manual stretch wrapping of pallets is particularly harmful to the spine. It results from a bent position forced by careful wrapping of the bottom layer of the pallet, and the weight of the stretch film roll (sometimes even 4 kg) additionally increases discomfort and risk of injury to the person manually wrapping the load

In summary, by choosing to purchase a professional pallet wrapper, we save time, reduce pallet wrapping costs, minimise the risk of poor load securing on the pallet, improve the aesthetics of pallet wrapping and take care of the health of our co-workers. Pallet wrapping machine is a fast returning investment ?

Types of pallet wrappers

Depending on the needs as to the efficiency and characteristics of the packed product, we can distinguish the following types of pallet wrappers:

- turntable wrappers. Rotating turntable wrappers are the most popular machines for securing pallets with stretch film. Due to versatility of construction these machines can be both manual wrappers and automatic pallet wrapping lines. Unquestionable advantage of turntable wrappers is their exceptional durability, easy operation and very good price to performance ratio

- ring and arm wrappers. Dedicated to wrapping high and unbalanced loads. Available in semi- or fully automatic version

- self-propelled pallet wrapping robots. They are an alternative to stationary wrapping machines. They prove useful where the user needs mobility of the device or the wrapped product cannot be transported to the wrapping machine due to instability of the load. Unquestionable advantage is lack of limitations in size and weight of wrapped products

Control panels used in pallet wrappers. Depending on needs and advancement of machine we use different control systems

Wrappers with motorized film stretching or friction stretching – what to choose?

Pallet stretch film wrapping machines can be equipped with various stretch film application systems. We distinguish between the following types of stretch film carts:

- cart with friction film stretching. It is most often used in manual and semi-automatic film wrapping machines. Film stretching is regulated by a friction brake – the more we block the stretch film, the more it stretches between the machine and a pallet. The advantage of such solution is reliable and relatively simple construction. For machines equipped with a friction film stretching system, we recommend using thinner prestretch or nano films 10-15 microns thick. Thanks to this solution, despite the lack of a professional stretch film stretching system, we can significantly reduce pallet wrapping costs. On request, the friction stretch film stretching system may be extended with an electromagnetic brake, which will enable us to smoothly control the film stretching from the control panel

- cart with a single-motor. This stretch film stretching system is most often used in semi-automatic machines. Single-motor stretch allows us to set a constant stretch of the stretch film (e.g. 250%) and independent adjustable tension of the film between the wrapper and the pallet. The level of film stretching is most often changed by replacing the gears (change of gear ratios) in the cart with film

- two-motor film stretching system. The most advanced design for smooth control and adjustment of both film stretching and film stretching. Two-motor stretch film stretching is usually found in automatic pallet wrapping lines as well as in more sophisticated wrappers such as Wrapper E Evolution

When deciding on a machine with a film stretching system, both single- and dual-motor, we have to take into consideration that the film used on those machines has to be of high quality and meet minimum stretching parameters. A common mistake is the purchase of an advanced machine that allows for e.g. 300% initial stretch of the film and the use of low quality stretch film on it, e.g. with a guaranteed stretch of up to 150%.

How to choose a pallet film machine and what to pay attention to

Due to the large number of available solutions, choosing the right machine to secure pallets with stretch film or net is not an easy decision. A huge spread of prices, a large number of models and different designs, a multitude of manufacturers – what aspects should we pay attention to when choosing the right machine

- service support. Machines for pallet wrapping often work in difficult conditions, therefore it is worth to narrow the decision about the choice of manufacturer or supplier to the companies having experience with this type of machines

- cost and availability of spare parts. Wrappers offered by some manufacturers or distributors may be equipped with non-replaceable control elements or untypical subassemblies dedicated only to a given type of machine or, for example, untypical motors, gearboxes. This often results in enormous costs of potential service, e.g. damage to the control panel due to mechanical damage or overvoltage may exceed the value of a 2-3 year old machine

- hidden costs and additional fees. It is worth getting acquainted with conditions and costs of such activities as inspections during warranty, costs of service travel. Wrapping machine purchase price is one thing, but often the aspect of additional costs is neglected. Offering machine in lower price we can often face situation that customer has to bear additional costs connected with e.g. delivery, assembly or keeping warranty

- use of appropriate technology. We know from experience that there are no fully universal machines. Remember to check whether a given machine is adapted to specific working conditions, e.g. if the machine is to work in an unheated warehouse, it should be equipped with an insulated control box; for conditions of high humidity or where machines are frequently washed (e.g. wrapping machines in meat factories), the use (at least partially) of stainless steel is required; if we are wrapping exceptionally heavy pallets, we should strengthen the machine base, etc.

- checking if the pallet wrapping machines meet CE standards. What we should pay attention to first of all are the systems of emergency stopping of the machine (emergency stop, protection of the cart with film against possible crushing of the user’s foot) and the execution of electrical installation – whether the manufacturer used shielded cables, whether the machine is properly earthed

Custom built pallet wrappers. Wrapper SA made of ACID RESISTANT steel and wrapping machine adjusted to wrap transport carts

Wrapper wrapping machines by Polpack – why it is worth to trust us

- our pallet wrapping machines come with a full 24 month warranty

- a network of branches in Poland ensures a quick realization of any order and immediate service of machines

- no hidden costs! In order to maintain warranty on the wrapper we do not require additional paid service inspections

- professional advice. Our specialists, having analyzed your needs, will suggest which model of the pallet wrapping machine will be the most suitable

- pallet wrappers produced by us are dedicated to specific expectations, requirements and working conditions of the machine

- as part of comprehensive service we provide delivery, installation and start-up by our specialists. During start-up of the wrapping machine we conduct training in operation and maintenance, and on your request we select appropriate stretch film together with sending you a report confirming film consumption, the exact cost of wrapping a pallet and the strength with which a given film stabilizes the wrapped load

- nearly 30 years of experience and almost 2000 wrappers delivered nd installed for customers in Poland and abroad

- thanks to cooperation with Millennium Leasing our machines are available in friendly financing – ask us about pallet wrappers leasing

Wrapper pallet wrappers manufactured by Polpack – overview of the model range

Since 1992 we have been manufacturing machines for wrapping products with stretch film or net. With full responsibility we can state that machines produced by us are among the most durable and reliable machines for securing loads on pallets with stretch film. The base of every wrapping machine produced by us are solid powder coated steel profiles, we use only proven electric and pneumatic components, and a professional team of people forming the production department builds “Wrappers” with the greatest care. These machines are thoughtfully designed to be as easy to operate and service as possible (e.g. we do not use integrated control elements). Each of our machines is thoroughly checked and tested before delivery to the customer. Currently, our model range of turntable wrappers is as follows:

Manually controlled Wrapper SM wrappers

Manual control, automation limited to the minimum, so to say. Dedicated to heavy working conditions and unique pallets – it is the operator who decides how each pallet is to be wrapped. It can be equipped with pneumatic pressure to stabilize wrapped load

Semi-automatic Wrapper SE pallet wrapper

Our basic model of semi-automatic wrapper. It has been a bestseller for more than 5 years – up to now (as of February 2021) it has won 650 users*. This stretch wrapper is already decently equipped in standard with, among other things, pallet height photocell, UNISTRONICS controller enabling personalisation and saving of programs, smooth adjustment of teh turntable speed, soft-start, friction film stretching. Wrapper SE has the possibility to work in a semi-automatic or manual cycle. Compact dimensions of the machine will be appreciated by companies with smaller storage space.

* applies to machines with different equipment versions

Product-specific pallet wrapping machines – Wrapper SA series

At first sight basic machine of SA series is very similar to Wrapper SE, but it is only appearance. Due to strengthened construction of the base these wrappers can be equipped with columns up to 5m high, 2000mm diameter disc, pneumatic pressure, door, window and cart holders, etc. As a standard, Wrapper SA pallet wrappers are equipped with multi-shaft friction stretch film stretching system or on request with single motor stretch film stretching system. These machines can operate in a semi-automatic or manual cycle. These machines are built from scratch with regard to individual needs of future users

Modern wrapping machines with stretch film stretching system – Wrapper E Evolution

Professional stretch film wrapping machines equipped with advanced two-motor stretch film stretching system which is smoothly adjustable from the control panel. These machines can be equipped with electric pressure stabilizing the wrapped load. E Evolution wrappers, as well as SA wrappers, are built from the very beginning so that they meet 100% expectations of future users

Automatic pallet wrappers working in line – Wrapper VO

Automatic machines for wrapping pallets with stretch film adapted to work in line or as a part of palletizing stations. These machines may be equipped with dedicated in-feed and out-feed conveyors, pallet turners, pallet elevator etc. They are equipped with a two-motor stretch film stretching system as standard. They can work with both EURO size pallets and industrial pallets

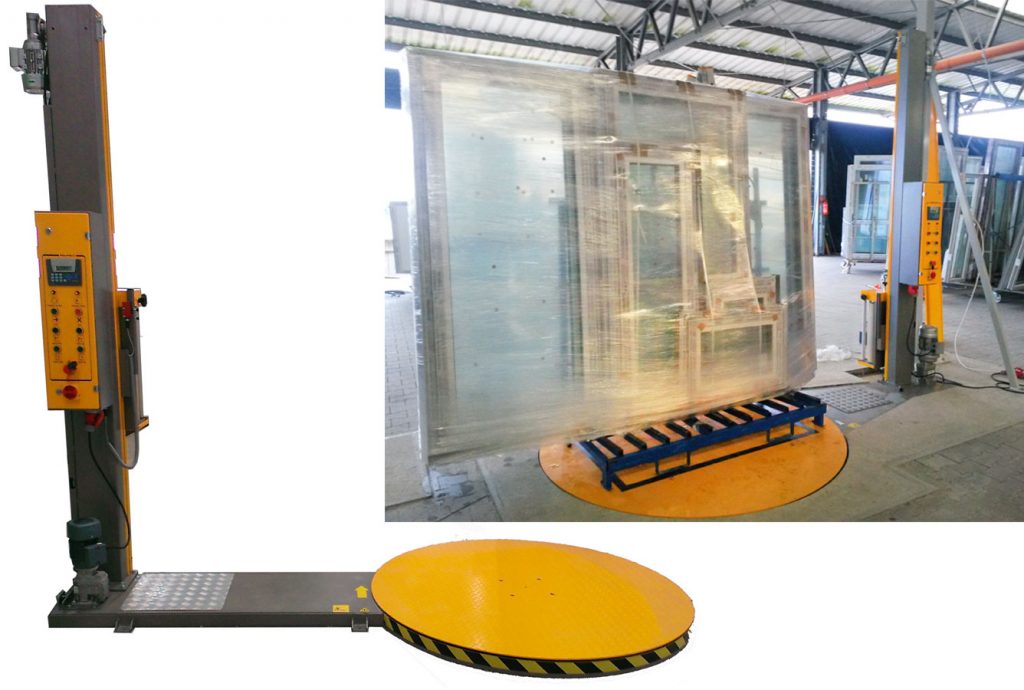

Machines for wrapping doors and windows in stretch film

The stretch film wrapping machines manufactured by Polpack can be adapted to packing doors, windows, gates etc. These are proprietary engineering solutions dedicated to the specifics of given production plants. Machines for packing windows, depending on the version, can wrap single windows as well as packs of windows placed on racks. For these wrapping machines we have dedicated handles and mounting systems for doors, windows, transport carts etc

Self-propelled pallet wrapping robots – LEO and LEONARDO

Manufactured by Italian company ITALDIBIPACK. They are alternative for the turntable wrappers. Self-propelled pallet wrappers are mobile devices, thus providing great adaptability in production plants. In our offer you will find various types of pallet wrapping robots: with telescopic or fixed mast, with motorized stretch film stretching system or frictional stretching of film

We optimize the selection of wrappers depending on your requirements, wrapped load, planned budget, etc.. When selecting the right model of packaging machine, based on our experience, we choose the right machine so that the load is properly stabilized and the stretch film consumption is as low as possible

Machines adapted for packing non-standard large pallets, crates, racks. On the left side wrapper with 1500mm turntable + additional extension of the base, on the right side wrapper with 2000mm turntable and extended base

Pallet wrapping machines – accessories

Each machine produced by us can be equipped with additional accessories depending on the needs resulting from the working environment, type of packed products, method of pallet loading. Below we present selected accessories with their short characteristics

Machines adapted for packing non-standard large pallets, crates, racks. On the left side wrapper with 1500mm turntable + additional extension of the base, on the right side wrapper with 2000mm turntable and extended base

Pallet wrapping machines – accessories

Each machine produced by us can be equipped with additional accessories depending on the needs resulting from the working environment, type of packed products, method of pallet loading. Below we present selected accessories with their short characteristics

- Frame for embedding the wrapper in the warehouse floor. It allows the machine to be “recessed” into the floor. The advantage of this solution is that the pallet can be loaded from either side of the machine. The lack of ramp reduces the required space in the working area of the machine and the turntable on the ground level makes it possible to load even the most unstable pallets

- Drive-on ramp for manual or electric pallet trucks. Drive-on ramp in the standard length of 1500mm, on request we make special drive-on ramps – e.g. adapted to long electric pallet trucks

- Clamping to stabilize the load during pallet wrapping. In our wrappers we use two types of clamping: electric and pneumatic. Pneumatic clamping is faster but has limited stroke (from 700mm to 1500mm) whereas electric clamping is a bit slower but works in the whole range of column height

- turntable with cut-out for pallet truck – so called turntable E. The rotary platform with cut-out for pallet truck allows convenient loading of pallets on the turntable without the need for a forklift or drive-on ramp. Thanks to the innovative design, the turntable entry can be set in any position

- Wrappers made of stainless or acid-resistant steel. Machines can be made entirely or partly from stainless steel. We recommend this solution for food and chemical industry. The machines can be additionally protected against water, moisture, dust and sub-zero temperaturę

- holders for specific products Smart mounting systems designed for e.g. doors, windows. We also make holders adapted to wrap transport carts

- automatic stretch film cutting system. It is standard in automatic stretchers such as the Wrapper VO, but on request we can implement this system in the Wrapper E Evolution wrappers

- stretch film rooping system. This solution is dedicated mainly to automatic high storage warehouses. The load is firmly wrapped to the pallet, and thanks to the stretch film rooping system, the film does not cover the space needed for the sensors, e.g. up to 100mm

- pallet wrappers with scales allow verification of weight of wrapped load. It will be appreciated both by persons checking the amount of assortment on the pallet and by transport companies which want to know exactly how much a transported pallet weighs

- smooth adjustment of the film cart travel allows precise adjustment of film overlap on a pallet. This option allows adjustment of the speed of the film cart movement in relation to the pallet to be wrapped

- extension of the standard base (with 1500mm diameter turntable) by additional 850mm enables wrapping of bigger pallets

- 2000mm diameter turntable is a dedicated solution for wrapping non-standard large pallets, racks (e.g. with windows) or crates

- upon request we also produce high pallet wrapping machines. Until now, the highest pallet wrapping machine for road signs had 5000mm column height

- control of wrapping machine clamping from the extension arm, so called rod. Option especially recommended for machines dedicated to pack doors or windows

Kamil Woliński