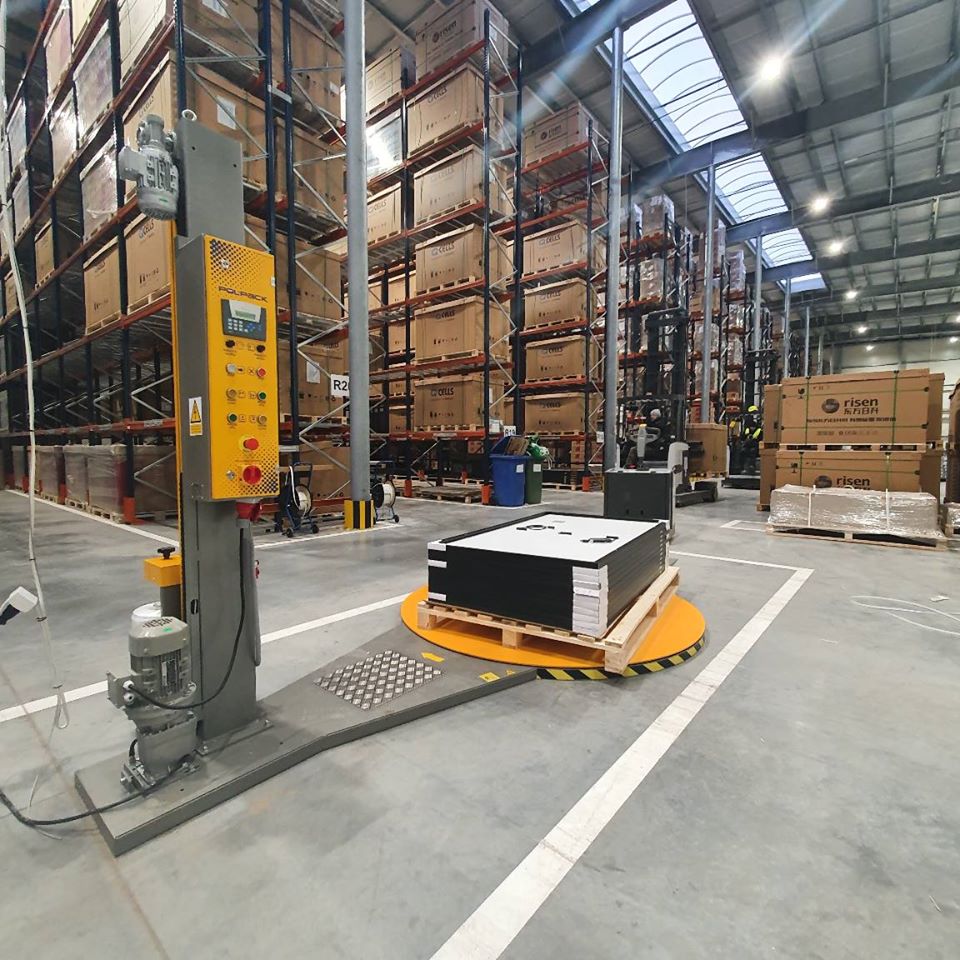

Automatic and semi-automatic pallet wrappers significantly improve the efficiency of warehouse or production facilities. Pallet stretch wrappers prevent some of the hazards associated with manual load wrapping such as back strain. However, like any machine, they can themselves pose a safety risk to users. It is therefore important that safety rules are followed when installing and operating these machines.

Pallet wrapping machine and safety risk

Some of the most common safety hazards associated with wrapping machines are:

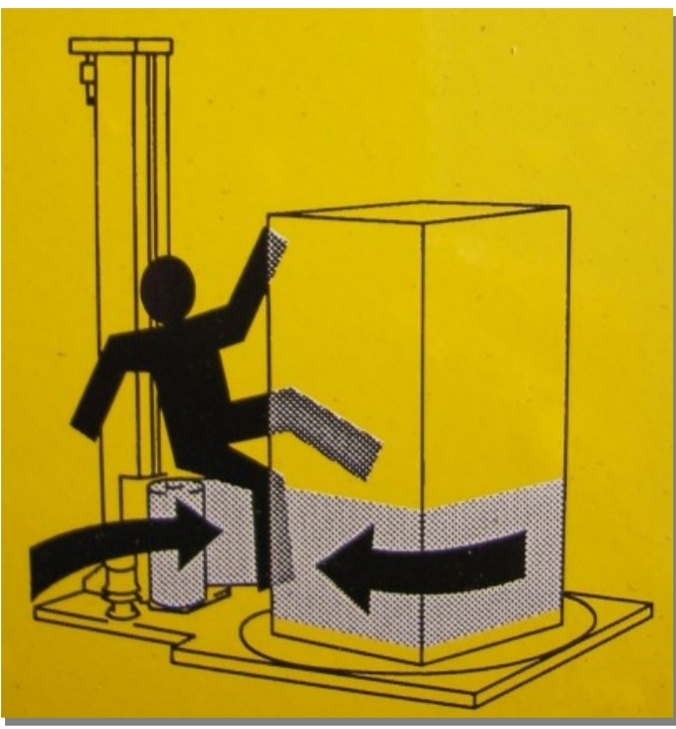

- Workers can be struck by moving machine parts

- Loose clothing can snag the wrapper during operation

- Injuries resulting from attempts to reattach the film after it has been torn off, for example

Your machine’s safety features can help minimize this risk, but there are other practical measures you can take to prevent possible injury.

Guidelines for safe installation of film pallet wrapper

When installing a wrapper, the following tips will make it as safe as possible for operators while maximizing its performance and overall efficiency and minimizing the risk of potential failure.

Install the wrapper on a solid, level surface

The first tip is to make sure that the pallet film machine is installed in the right place. The floor should be even and stable. If it is unstable or uneven, it may create a risk of crushing the operator and may cause damage to the filming machine.

Be careful when transporting film pallet wrapper

When moving the wrapping machine, make sure you use a forklift with adequate capacity. The forklift should be heavy enough to prevent tipping over when moving the pallet wrapping machine. It is also strongly recommended that you avoid trying to push or move the machine. This can cause damage to the machine and even injury to those involved in the installation of the machine.

When connecting a pallet wrapper, avoid using extension cords

Extension cords carry several risks, including tripping and electrocution. When connecting power to your wrapper, make sure it’s close enough to an outlet so you don’t have to use an extension cord.

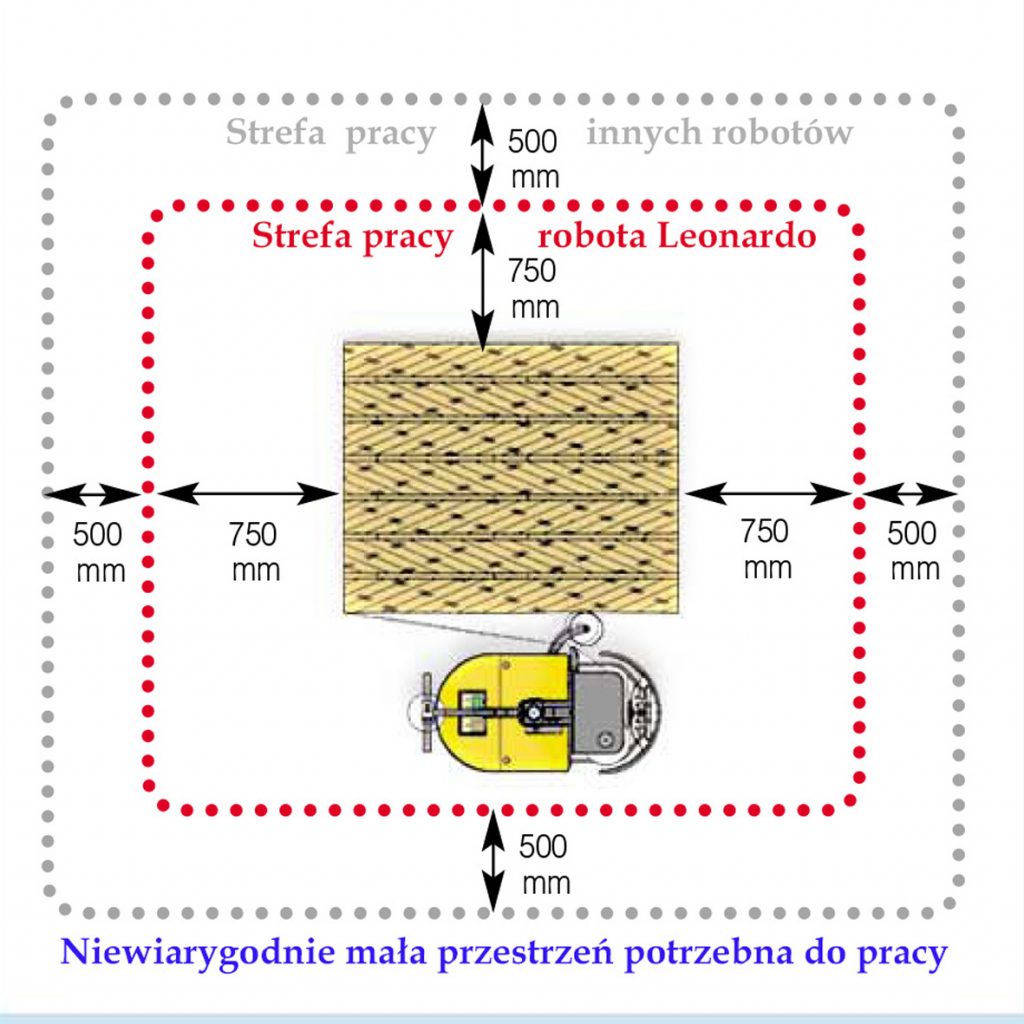

The danger zone of a pallet wrapper is between the column and the pallet to be wrapped

Screen off the machine work area and install safety barriers

Automatic wrapping machines or machines designed to wrap unusual, large pallets should have a cordoned off work area. Operators should also be trained to use the safety barriers as intended

Once installed, a stretch wrapper significantly reduces the risks associated with wrapping loads compared to manual wrapping. However, it is important to remember that this is heavy equipment with many moving parts, so it is important that operators are properly trained in proper safety practices.

Pay attention to the maximum weight of wrapped pallets

Above all, do not wrap loads that exceed the maximum allowable load of the stretch wrapper. In addition, when wrapping with stretch film oversized loads which protrude beyond the rotating disc, particular care must be taken to ensure that the protruding parts do not damage the machine (column or other protruding parts) and do not pose a hazard to persons in the vicinity of the wrapping machine.

Therefore, always make sure that the pallets you are wrapping fit on the turntable and do not exceed the maximum weight indicated by the manufacturer. If you need to wrap larger loads, it is worth investing in a larger wrapper.

Keep your distance from the turntable

When operating the pallet wrapper workers should maintain a safe distance from the load to be wrapped and the turntable. The machine should be designed so that the control panel is away from the turntable, making it safer for the operator. Particular care should be taken by those in the vicinity of the machine

Wrapper pressure control from boom with emergency stop installed

Switch off the pallet wrapper when not in use

As with many pieces of heavy equipment, it is always good practice to make sure your pallet wrapper is turned off when not in use. Not only will this save electricity in your facility, but it will also reduce the risk of the machine starting up unexpectedly when someone is around.

Disconnect the pallet wrapping machine from the power supply before servicing

Every time you want to service a machine, turn it off. Adhering to health and safety regulations prevents potential accidents, and following proper maintenance and lockout tagging at your facility is always a good idea and no different than a stretch wrapper. Whenever you plan to maintain your stretch wrapper, first turn it off and disconnect the power.

Regular maintenance of pallet wrapperst

Pallet stretch film packaging machines require regular maintenance to function properly. Recommended preventive maintenance tasks include:

- Gearbox oil inspection

- Lubrication of the film trolley slides and chains

- Chain tension check

- Inspection of electrical installation

- Machine calibrations

We recommend checking the condition of the pallet wrapping machine at least once every quarter. However, the frequency of maintenance depends on the operating conditions of the machine, the type of pallet loads being wrapped and, of course, the number of pallets wrapped.

Keep the machine and its surroundings clean. Your pallet wrapping machine should be cleaned daily if possible, and debris such as pieces of film, pallets should be removed from the rotating plate. This will keep your pallet wrapping machine running smoothly while minimizing the risk of machine failure.

Window wrapping machine equipped with a safety sensor, protects against hitting the window on the column of the machine

Safety when using stretch film wrapper

When your employees are trained to follow the above pallet wrapper safety tips – and if your work process supports their implementation – you will benefit from increased job safety and machine reliability.

As a manufacturer of pallet wrappers, we make every effort to make our machines as safe for operators as possible. More information about our pallet wrappers you will find under this link.

Józef Woliński